Our Products

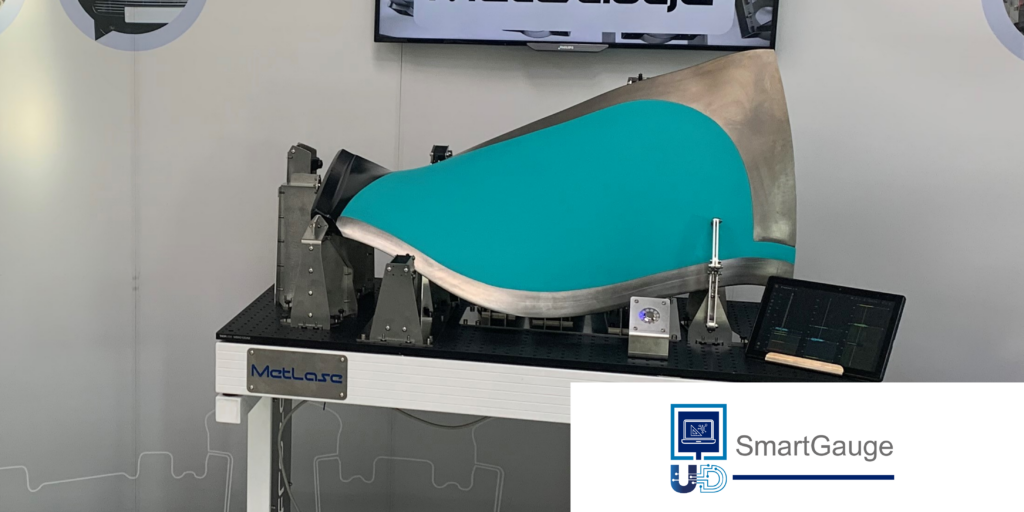

SmartBench

MetLase have developed SmartBench, a digitally-enabled assembly workstation for manual manufacturing processes. The workstation enables companies to implement Industry 4.0 technologies in a way that is customised to their specific need, covering almost all manual manufacturing processes.

Data collected throughout the process is automatically analysed, to drive further data-driven process improvements.

The ‘no-fault-forward’ approach is designed to eliminate production defects by delivering 100% quality.

SmartGauge

Our SmartGauge is a digital inspection tool that enables you to measure components very quickly. It then provides a comprehensive level of information to enable you to make improvements to components and processes.

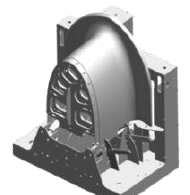

Inert Gas Welding Shields

Patented gas management techniques guarantee an oxygen-free environment, for quality-critical welds.

MetLase gas shields have a shape which is customised for your application, to distribute an even flow of welding-gas, precisely where it is needed, without gaps in coverage, but also without waste. The shield can incorporate a mechanism to track the movement of a welding head. MetLase gas shields can achieve better than 10 ppm shielding from atmospheric gases.

This case study explains the use of gas shields.

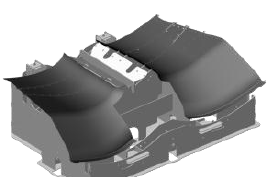

Pipe and Duct Assembly

Part scribing, tack welding and assembly of pipe-work incorporated into a single build fixture.

MetLase fixtures hold pipes and ducts in place, while they are welded. The frame can be constructed so as to allow complex arrangements and access for welding, yet parts are aligned with high-precision. Loading and unloading of parts is rapid, using titanium sprung, over-center-clamps. We can also adjust the precision, whether you need to enforce a perfect “aerospace-grade” alignment, or the fixture must accept parts with wider tolerances. We can also iterate the design: this is useful for car-exhaust prototyping when multiple variants must be tried to get just the right sound.

This case study uses our pipe-and-duct assembly techniques.

Laminate Press-brake Tooling

Press-brake forcing tools are normally complex and time-consuming to make, and required in very specific shapes. MetLase can produce them to high precision, and in a matter of hours. We use them extensively ourselves.

This case study illustrates the use of laminate press-brake forcing tools.

Fast-make Components

Patented computer numerically controlled (CNC) press-brake techniques used for producing low-volume bespoke brackets and clips.

The most common application of MetLase is for making tools. But we can also make the products themselves, in smaller volumes or for prototypes.

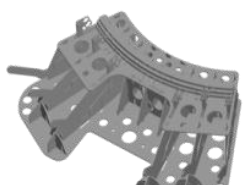

Inspection Fixtures

Metrology fixtures, designed to support a part, without distorting it, so that it can be measured to high-precision on a co-ordinate measuring machine (CMM).

This can sometimes be very challenging when the inspection is needed from awkward angles, or the part might distort under its own weight.

This case study illustrates the the use of an inspection fixture.

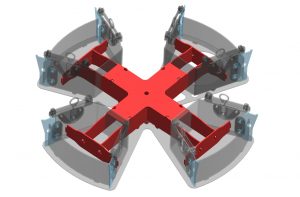

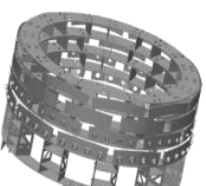

Component Build and Assembly

High precision fixturing solutions for component and engine assembly requirements.

This case study is an example of an assembly fixture

Chipless Machining

Unique fast-make methods for accurate component location, in readiness for 5-axis laser and water-jet cutting.

Mechanically Optimised Fixtures

Mechanical stiffness maximised, ensuring stable location and clamping of structures during part-making and machining.

This case study illustrates a MetLase fixture used for machining.

Special Process Fixtures

Location and clamping of hot-end engine components for application of thermal barrier coatings.