Dean Langford has been appointed Managing Director, MetLase

With over 20 years’ senior engineering, manufacturing and supply chain management experience for businesses including McLaren Racing, Cullum Detuners, Ishida Europe and most recently Safetykleen, where he was Managing Director, Group Manufacturing, Dean has a strong track-record of developing high performing, multi-disciplined teams throughout the manufacturing supply chain, and leading businesses through periods of significant strategic and operational growth in the UK and EMEA.

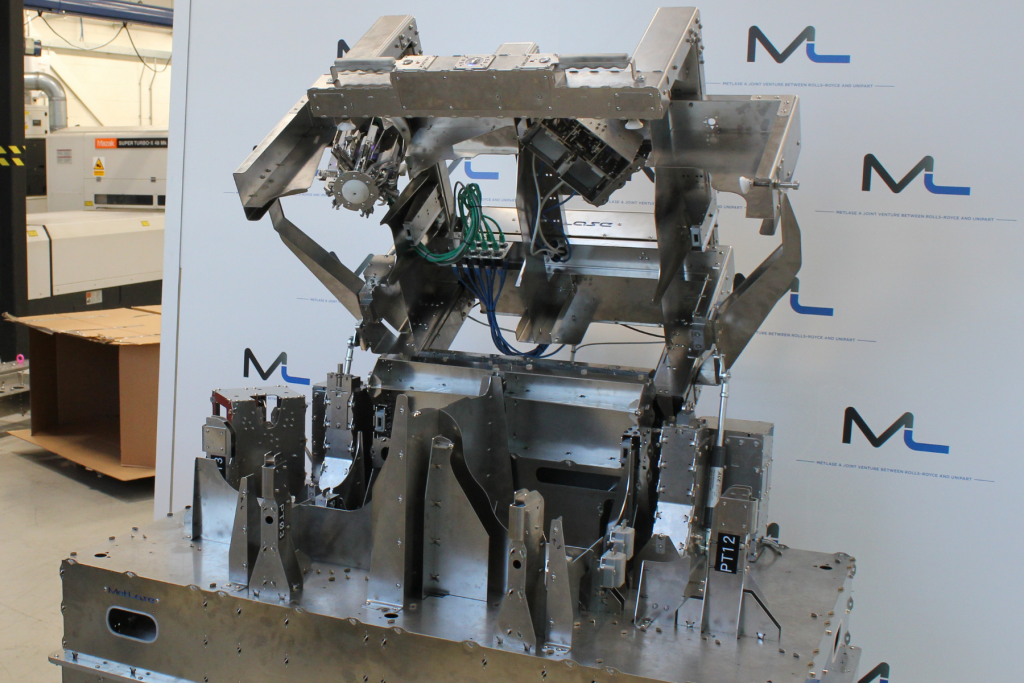

MetLase launches two ‘digital benches’ at Smart Factory Expo

Metlase will showcase its Component Assembly Bench and Repair Bench at this year’s Smart Factory Expo, taking place in Birmingham (June 7-8) as part of Manufacturing and Engineering

Week.

We are exhibiting at Engineering Solutions Live

Returning to the British Motor Museum in Gaydon on Thursday 23rd March 2023, Engineering Solutions Live is your one-stop-shop for new contacts and thought leadership in the engineering sector.

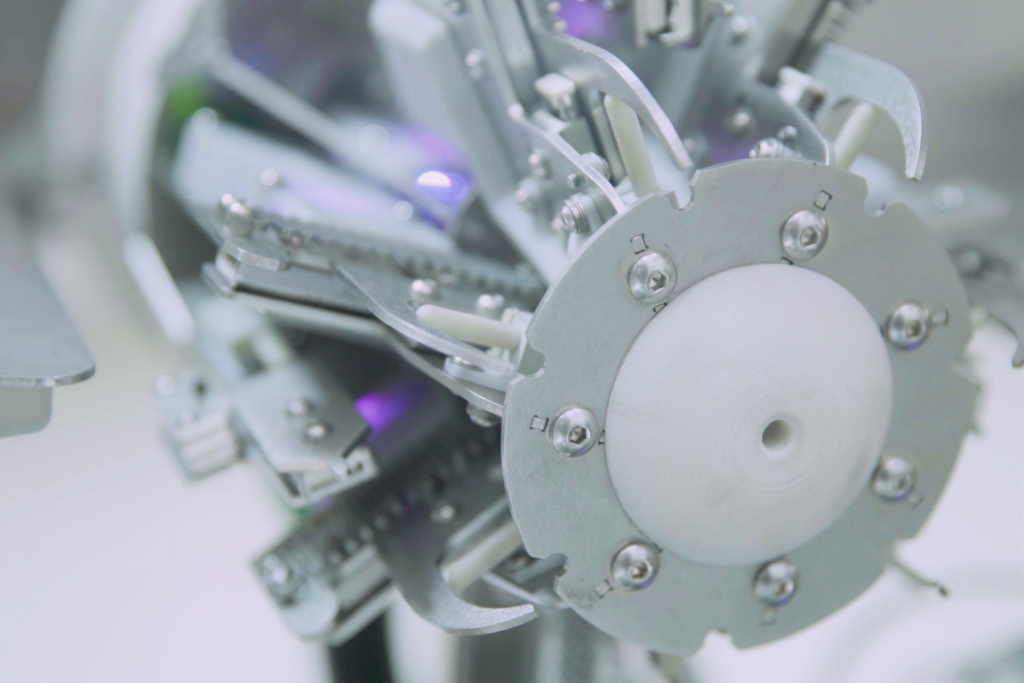

Stewart Lowth leads digital transformation based on the practical approach honed from MetLase’s expertise in tooling and fixturing

For Product Development and Innovation Manager Stewart Lowth and the team, getting the right data to the right people is crucial to making informed decisions.

A sensor of perspective

Digital transformation is taking a firmer grip on modern-day manufacturing. Leading the charge is MetLase using ‘advanced sensor technology’ to deliver innovations that contribute to ‘greener’ travel.

MetLase supports Rachel Reeves MP visit

Rachel Reeves met teams at Hyperbat, Unipart’s EV battery manufacturing joint venture, and MetLase, Unipart’s smart tooling company.

MetLase supports sculpture artist to construct sporting commission for Commonwealth Games

MetLase is among the UK’s most cutting-edge technology manufacturers supporting sculptor Jacob Chandler with his commission for the Birmingham 2022 Commonwealth Games.

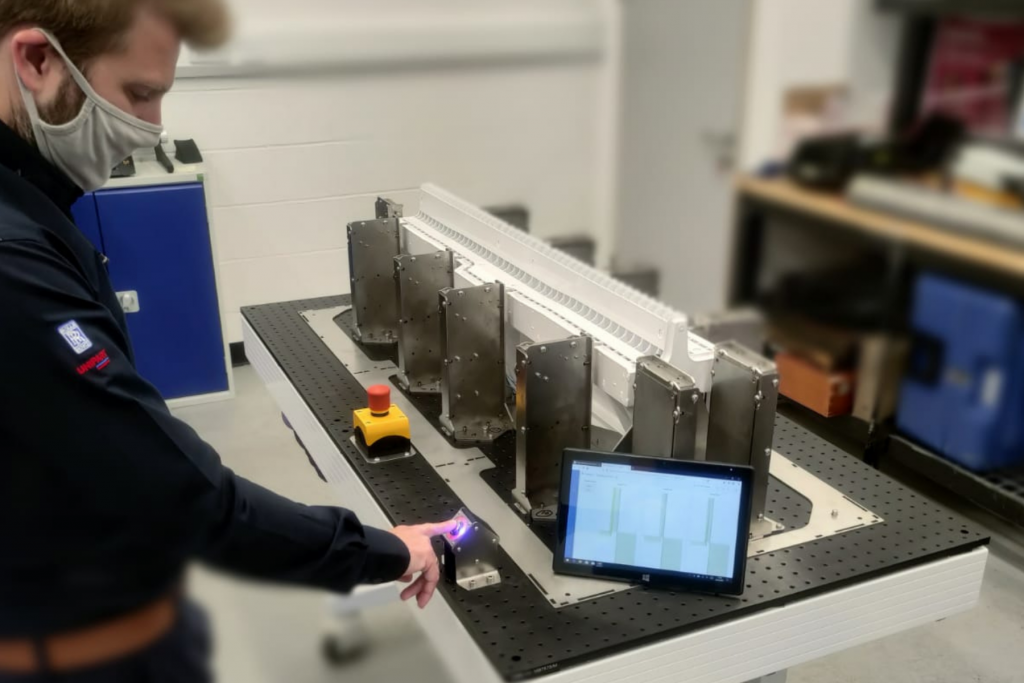

MetLase SmartBench demonstrates the art of the possible at the UKRRIN Technology and Innovation Hub

The MetLase SmartBench will play a key role in the development of new technologies and solutions for the rail industry.

MetLase SmartGauge technology seamlessly integrates into the NCC’s Made Smarter Innovation Hub

Adopting digital tools and doing things differently, particularly when thinking about improving efficiencies and resiliency, has been amplified by the COVID-19 pandemic. MetLase have been selected to showcase their Digital SmartGauge at the National Composites Centre (NCC) Smart Factory Innovation Hub. A great opportunity to offer virtual and physical digital testbed environments, providing manufacturers the chance to explore new value propositions of digital transformation.

How Horizontal Innovation enhances your business agility

In one of the most disruptive years in manufacturing, some businesses have embraced and accelerated their digital journeys while others were required to put digital transformation on hold and are now playing catch-up. In both of these cases, businesses can benefit from MatLase’s approach.

MetLase challenges the manufacturing sector to go digital

MetLase, one of the UK’s leading specialists in tooling, intelligent fixturing and components, is launching a new range of ‘digital’ solutions that will connect manufacturing processes and enable easier, faster automation.

Re-engaging Innovation

The Covid pandemic has completely changed how we operate. The quick adaptation to multiple new working patterns such as remote working, blended working and virtual meetings have required us to rapidly adapt to change.

MetLase pay tribute to colleague with tough 1000km challenge

The MetLase team took on the 1000km challenge during June in tribute to their friend and colleague, Toby Unna who sadly passed away in April following a long battle with leukaemia.

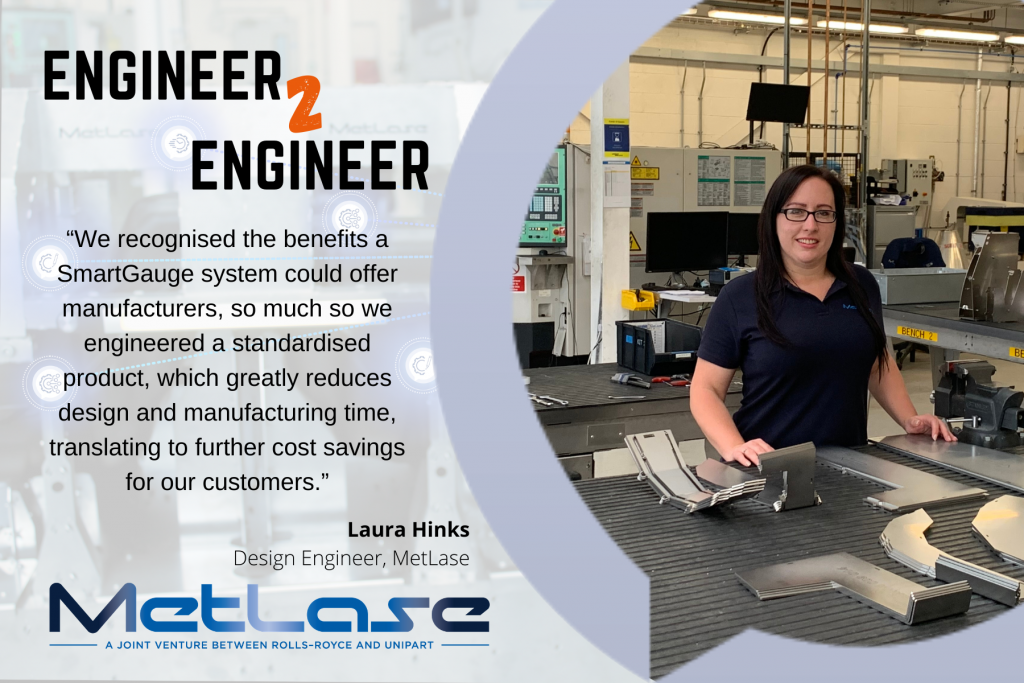

Engineer to Engineer: Developing SmartGauge

In a world dominated by smart technology, MetLase offers a variety of solutions to everyday manufacturing problems. But what does this really mean? If we want manufacturers to invest and adopt our technology, we need to give a clear insight into the real benefits that can reduce costs, improve your processes and be first to market.

New digital technologies set to deliver 20% growth ‘birthday present’ for MetLase

MetLase, which is a joint venture between Unipart Manufacturing and Rolls-Royce, is launching a new expansion plan that has speed, customisation and data at its heart through the launch of ‘smart’ products that give its global customer base the ability to reduce costs and be first to market.

MetLase appoints Johnathan Andrews as Business Development Manager for Digital Products

MetLase is delighted to announce the appointment of Johnathan Andrews as Business Development Manager for Digital Products.

MetLase invests in digital growth and creating technology jobs in Sheffield

MetLase has invested £565k in Sheffield City Region to create engineering jobs and take a series of digital products to UK and global manufacturing markets.

Three is the magic number

Manufacturing is having to contend with unprecedented challenges, but with challenges come opportunities if they can access the magic ingredients of speed, customisation and digital technology.

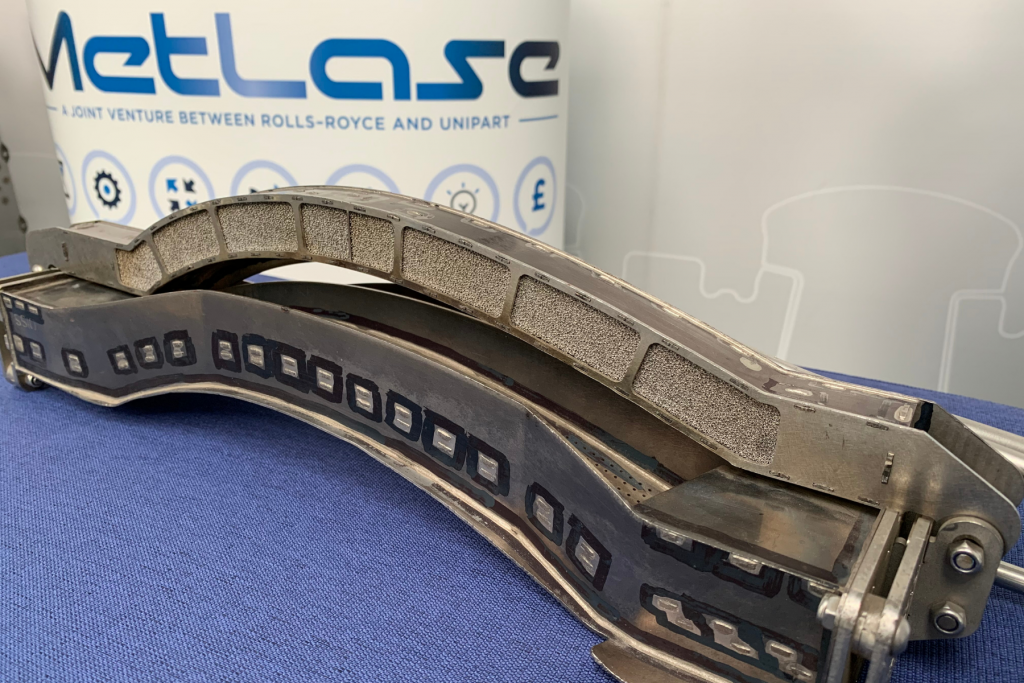

MetLase develops digital enhancement for tried and tested Gas Shield technology

Engineers at MetLase have been developing Industry 4.0 sensor technology to monitor welding processes within the aerospace industry.

My Year in Industry – Heather Price

Currently studying Biomedical Engineering, Heather took an opportunity to take her knowledge to the next stage and exploit the process, applying it to a Mechanical & Digital Engineering company with a vision of growth.

MetLase launches the Digital Gauge

Richard Gould, Business Development Manager at MetLase, attempts to remove some of the myths around digital manufacturing and why engineers should focus on digestible and actionable data as part of the bigger picture.

Digital Evolution not Revolution

Richard Gould, Business Development Manager at MetLase, attempts to remove some of the myths around digital manufacturing and why engineers should focus on digestible and actionable data as part of the bigger picture.

Developing my career with MetLase

After just 3 years with MetLase, Stewart Lowth has recently been promoted to Product Development and Innovation Manager

How do you flex your manufacturing to respond to COVID-19 and reshoring needs?

Industry hasn’t really seen anything like the sudden changes the pandemic has thrust upon it, and there is now a massive need for manufacturing to be more flexible and rapidly adapt to a changing economic picture.

Rapid Reaction

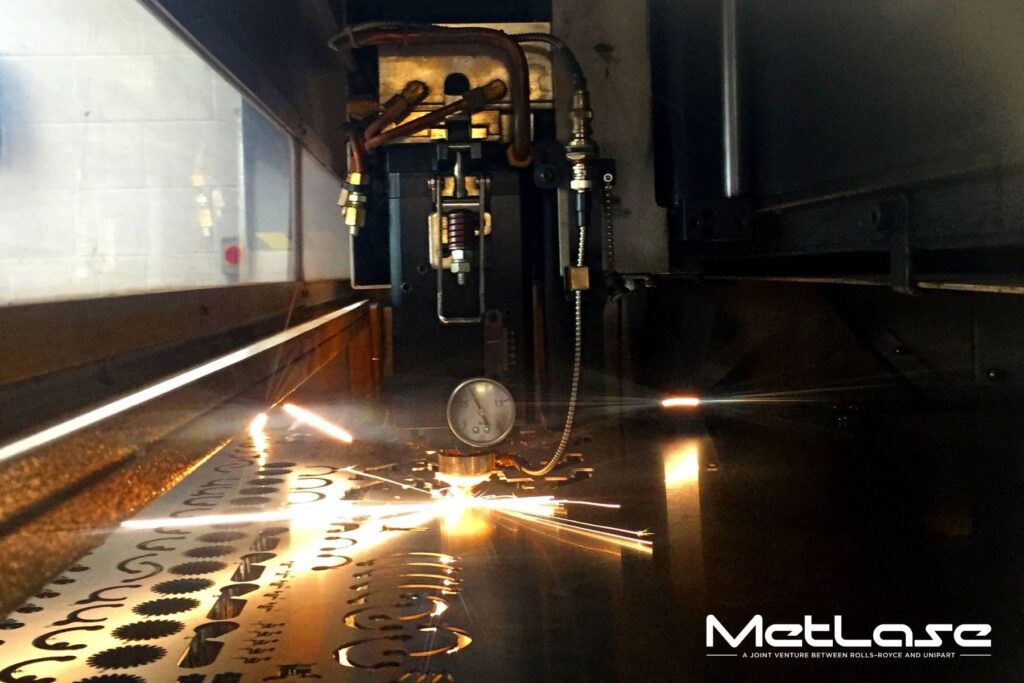

Whether it’s supplying just-in-time for car manufacturers, developing safety critical components for aerospace or being first to market with a new product, the demand for shorter lead-times is growing

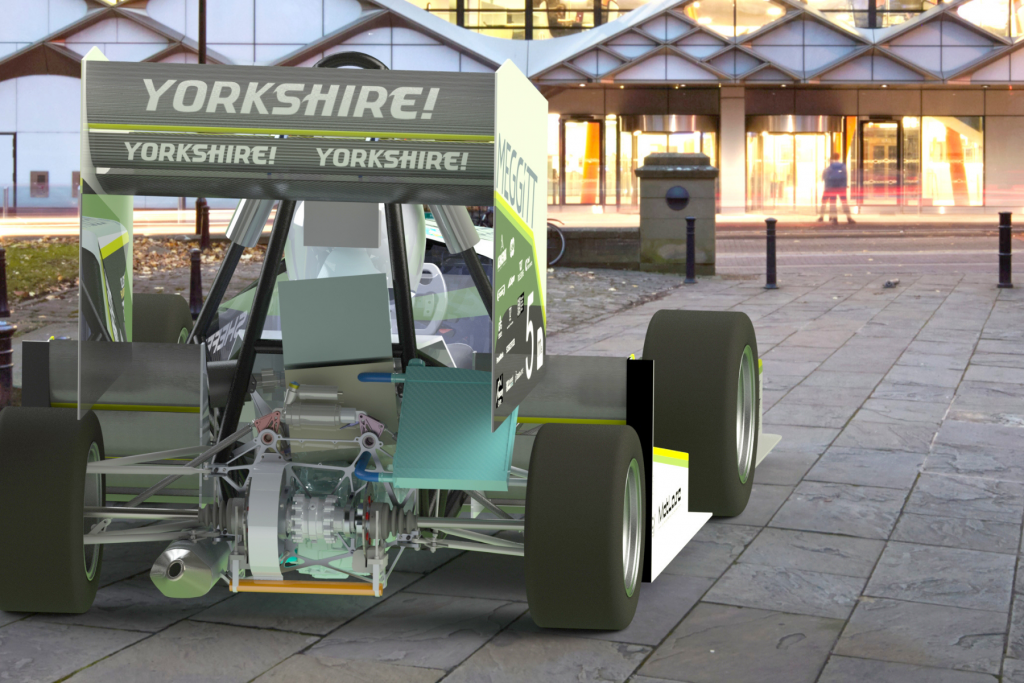

The Drive of their Lives!

The very best University educations take place as much in the world of commerce as they do in the lecture theatre. For the last four years MetLase has been part of the development of The University of Sheffield’s Formula Student team ‘Sheffield Formula Racing’.

MetLase chief urges industry to ‘flex’ its technologies to support Covid-19 recovery

Steve Dunn, Managing Director of Rolls-Royce and Unipart joint venture business MetLase, believes the firm’s pioneering work in the Ventilator Challenge UK consortium highlights how technology proven in the aerospace sector has been used in other sectors to help build the country’s manufacturing resilience and support reshoring activities that are slowly picking up pace.

The Manufacturer cites MetLase as a good example that shows UK manufacturing is as buoyant as ever

Following the recent announcement to become the tooling and fixturing partner for Boeing Sheffield’s new manufacturing facility, MetLase are proud to be recognised by The Manufacturer as evidence that the UK’s manufacturing sector is as “buoyant as ever”.