Guided System for Restricted-Access Machining

Enabling accurate profile control for in-situ/in-service machining operations.

Introduction

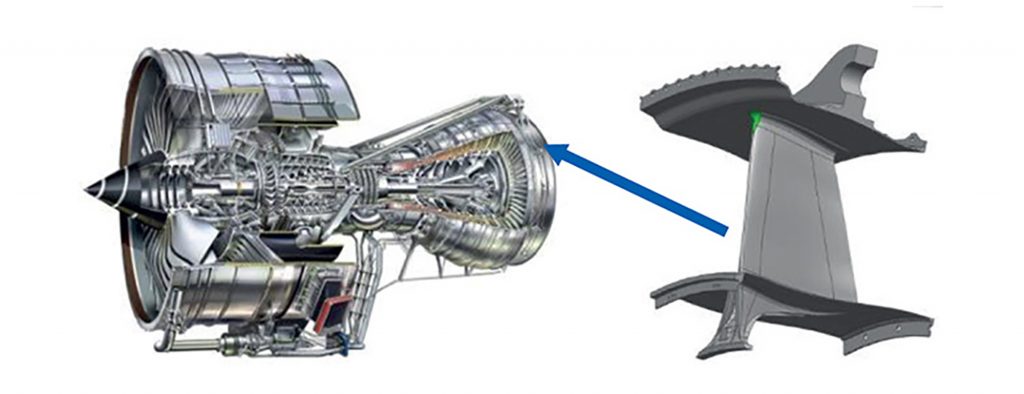

Maintaining the profile of all elements of an engine on the wing is essential to the aerodynamics of an aircraft. This includes the vanes of the tail-bearing housing, which support the rear of the engine behind the turbine.

MetLase was asked to produce a method for on-wing machining vanes to a controlled aerodynamic profile.

Solution

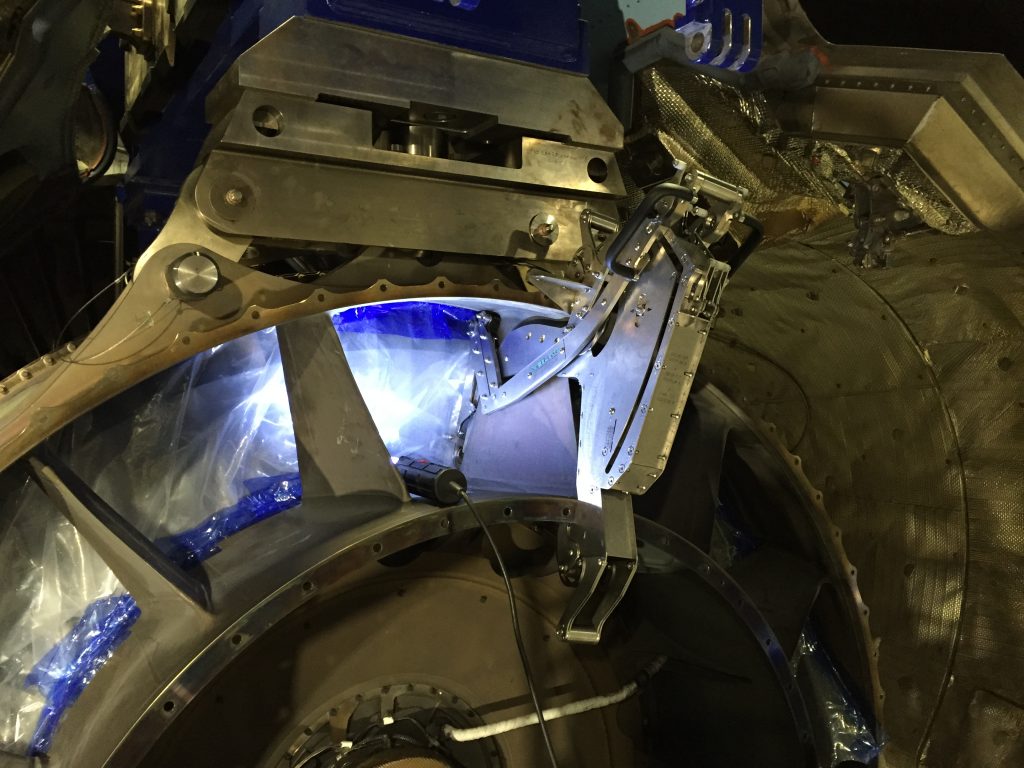

The profile of the vane is complex; MetLase was able to design, produce and iterate a bespoke pantograph, precisely engineered to be attached to the vane to produce the required form when re-machining.

Created using MetLase’s precision laser cutter and proprietary joining technologies, the pantograph could be used on the vane in situ, precluding any need for engine disassembly.

Benefits

The pantograph’s ability to be used in situ, despite a complex environment with poor access, resulted in significant savings in both time and cost. Additionally, the ease and precision of its tooling de-skills its operation, reducing the need for only highly-trained engineers to use it.

Summary

Cost: In situ machining operation does not require engine disassembly saving time and cost.

Fast Make: MetLase was able to rapidly iterate the development of a bespoke pantograph machining tool to produce the required form.

Solution: Tooling de-skills operation and enables the machining process in a complex environment with poor access.